|

Startup

<click on the picture>

|

Some

vid`s of the startup |

|

Assembly

<click on the picture to get more

pics>

|

Crank sensor, electric water pump, fuel

pressure regulator,

exhaust, mounting the engine

management, injectors,

plenum, ignition

|

|

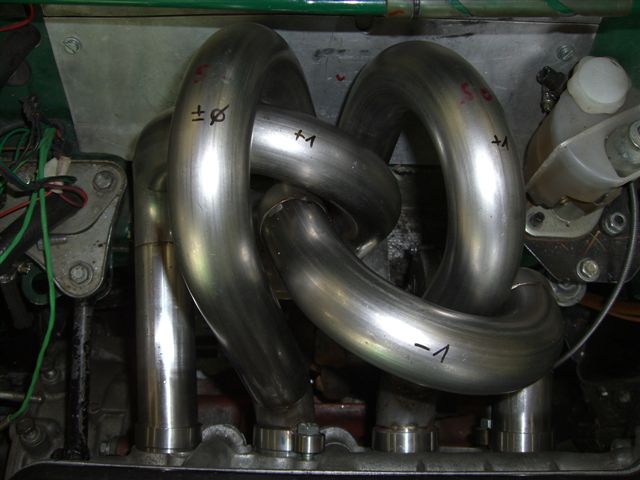

Exhaust

<click on the picture to get more

pics>

|

The

“Gordian knot” is ready to feed the hungry turbine. It is made of mandrel

bend stainless

steel bends, the primaries are equal length 20” +/- 0.4”. I was

trying to use as few parts as possible to reduce the number of

welds – would

not do it this way again – wasn’t worth the

hassle.

Each primary received a thermocouple bung, also a bung for

measuring

turbine inlet pressure was added to judge different

A/R housings. |

|

Inlet system

<click on the picture to get more

pics>

|

The

plenum is finished. The throttle body was “borrowed” from a

Jeep;

it is very compact and also has a build in stepper motor

for good idle control.

|

|

In car test

<click on the picture to get more

pics>

|

I

did not believe my eyes that I still could use the original

bonnet with my

adapted Honda pulleys, but there is only about

5mm space left between the

bonnet and the edge of the BMW valve

cover.

|

|

16V Bimmer head

<click on the picture to get more

pics>

|

The coolant flow was changed to a more efficient path; also the floor

of the inlet ports was welded and

raised to improve airflow. The water

outlet of the head will be

positioned new to avoid air pockets;

an ECU

controlled electric water pump will control water temperature.

Some

welding and milling had to be

done to accept the new side cover. |

|

Clutch plate

<click on the picture to get more

pics>

|

A

Tilton sinter metallic clutch plate was modified to accept the

Mini centre.

Luckily a friend of mine is working at MIBA, where these plates

are

produced for Tilton.

|

|

Crank

<click on the picture to get more

pics> |

The

crank was wedged to receive a better weight distribution of the

counterweights.

|

|

Turbo

<click on the picture to get more

pics> |

I

built a hybrid turbo with a bigger and better compressor (with

very good

and broad efficiency islands), therefore I had to

reduce the height of the

wheel a little bit. The

setup was balanced after assembly.

|

|

Oil pump drive (cam?)

<click on the picture to get more

pics> |

The

hottest cam an A-Series has ever seen: 360°! I turned the lobes

down

in the late at my machinist – the faces of the other

customers that day were

priceless.

|

|

Con rods

<click on the picture to get more

pics> |

Innocenti rods have been lightened to about 590g; here some

pictures before

polishing.

Forged Omega 15cc pistons will be fit

to these rods.

|

|

Block modifications

<click on the picture to get more

pics>

|

a)

The original holes were threaded and closed; then the new

threads made

for the ARP bolts.

b)

Piston under crown spray jets will find their way into this

block again.

c)

For the oil return I welded some “ears” to the block, then 2

tubes where

pressed in, to obtain a trouble free system. So I

still can use the original

BMW steel head gasket. Oil supply for

the head was also relocated slightly.

My

machinist loved me for doing that (when he had to deck the

block),

because the material hardened up in the welding area of course.

d)

The block was bored and honed with a torque plate to obtain

round bores

when the head is torqued down. But bore measurements

after removing this

plate showed that it wasn’t worth the

effort. |

|

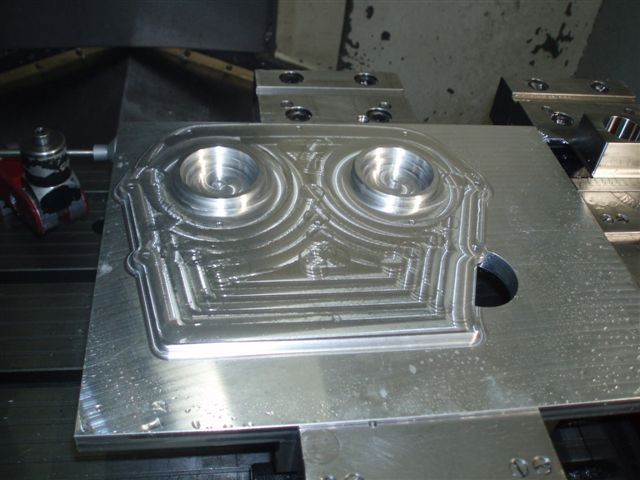

Covers

<click on the picture to get more

pics> |

Constructed by myself, milled by my brother on a CNC. For these

nice parts

I had

to learn

to work with CAD. Took me a lot of

time to learn CAD and

construct

these parts. I

was

trying to get my pulleys as near as possible to the

first

cam bearing to reduce the leverage

and therefore load for this

bearing.

|

|

Cam pulleys (3x)

<click on the picture to get more

pics> |

Modified Honda wheels; I took them because they have a small

diameter and

I got

them

for free from a friend who is modifying

Honda engines. Cam timing

is adjustable

of course.

Bottom Honda pulley was modified and pressed on a

custom part.

|

|

Backplate

<click on the picture to get more

pics> |

Lightening was also done in a CNC mill; I also did a lot another

22G270

backplates

for

my Mini friends at this time, so we could

reduce the costs

for milling.

|

|

Engine management

<LINK> |

A

Megasquirt EFI will find its way into my car for fuel and spark

control.

<schematic

diagram>

|